Civil Engineering Structure Inspection Service

We investigate the safety of structures with specialized techniques

Sugitec's civil engineering structure inspections are realized through the utilization of cutting-edge technologies including the 'Cooled Infrared Camera', 'Ultra-high Pixel, Ultra-telephoto Camera + Automatic Analysis System', and 'Smart Inspection Tablet System'. These solutions ensure the accuracy and reliability of inspections while significantly streamlining operations, leading to cost reduction.

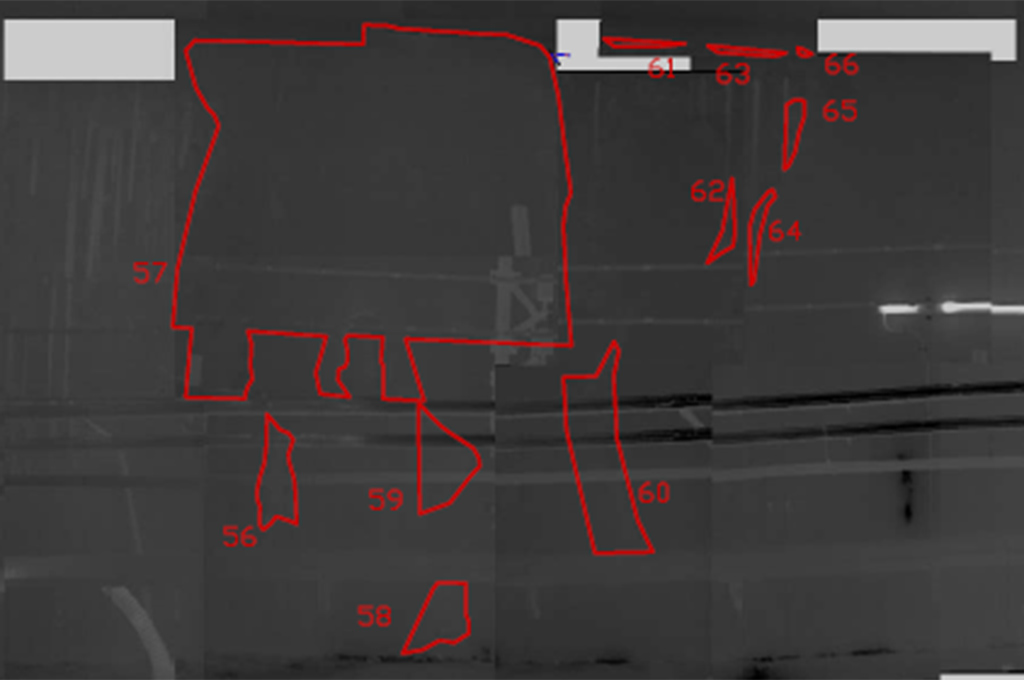

The technology to accurately detect deteriorated areas in concrete structures.

The technology for structure uplift survey

Cooled infrared camera

- Infrared inspection is possible even in environments with minimal temperature changes, such as the north side of buildings.

- It is possible to conduct inspections in environments without sunlight, such as subways and tunnels.

- Utilizes cutting-edge temperature detection sensor technology capable of distinguishing temperature changes of less than 0.02°C.

Crack inspection technology for structures

Ultra-high resolution camera + automatic analysis

- The ultra-high-resolution camera can capture a wide area in high quality with just one shot.

- Photography with a super-telephoto lens allows for high altitude shots.

- A system that automatically detects cracks, thereby streamlining the analysis process.

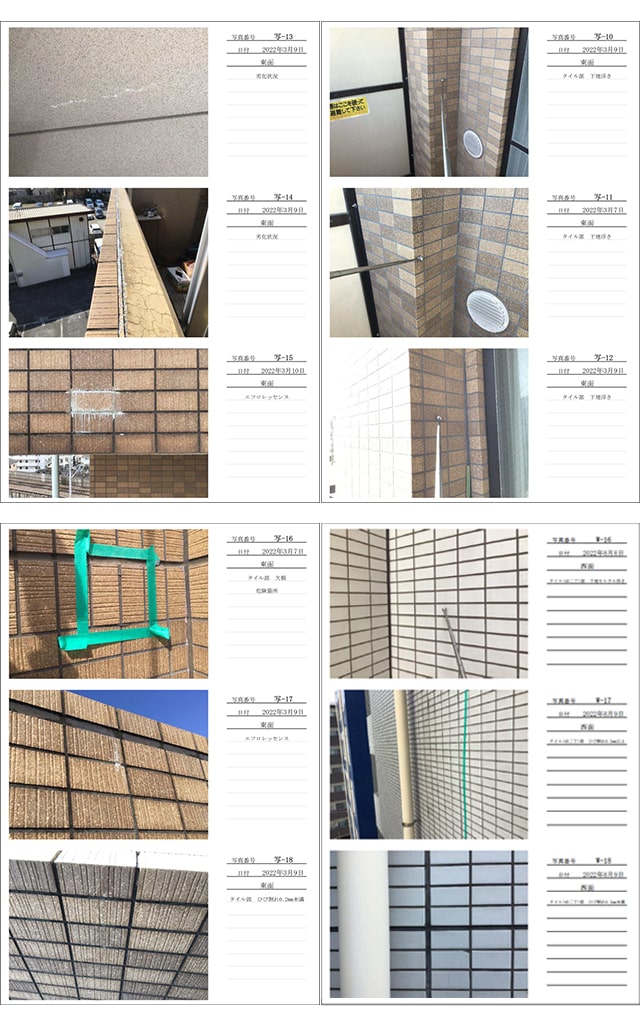

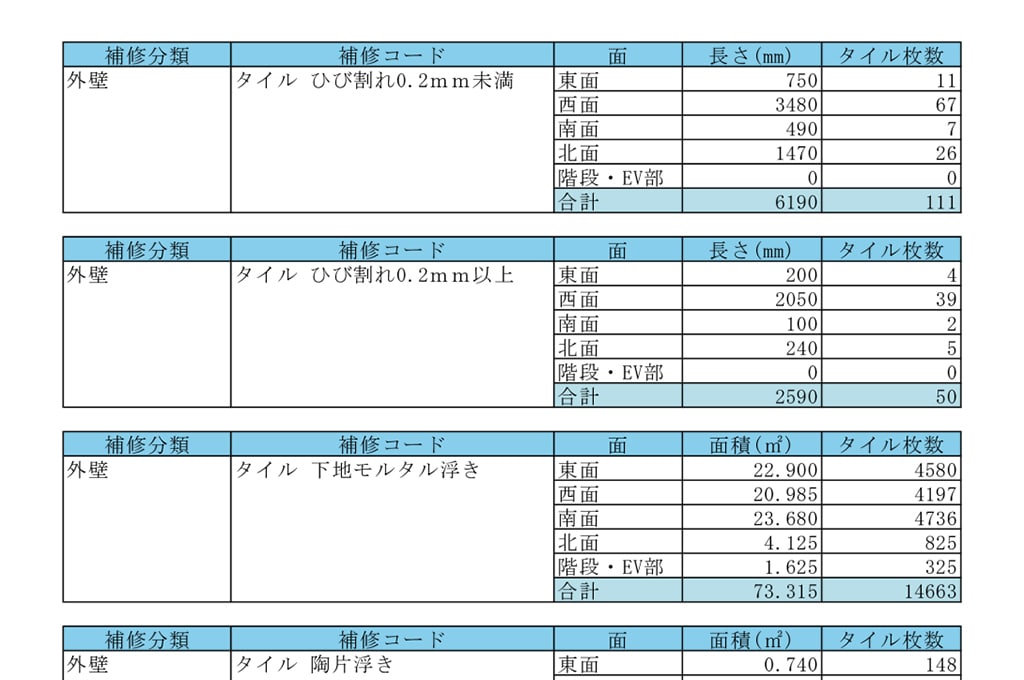

Precise inspection technology before repairs

Smart Inspection Report Generation Software ST

- By conducting initial inspections of deteriorated areas with the app, it's possible to accurately grasp deterioration information.

- The report can be generated with a single click, significantly streamlining the workflow.

- The investigation status can be timely checked on the cloud. It can also be utilized as a progress management tool.

Infrared inspections of structures in environments without sunlight are also possible.

Cooled infrared camera

In environments such as subways and tunnels where sunlight does not penetrate, conducting infrared inspections typically requires the use of the active infrared method, which involves artificially heating the concrete surface with a heat source. However, by utilizing highly sensitive cooled infrared cameras, measurements can be taken in their natural state without the need for artificial heating, resulting in cost and time savings.

Inspection Equipment: FLIR A6701sc

Equipped with a state-of-the-art cooled indium antimonide (InSb) detector, it offers high-precision temperature resolution of less than 0.02°C, which is more than double that of conventional uncooled infrared cameras, allowing it to capture extremely subtle temperature changes.

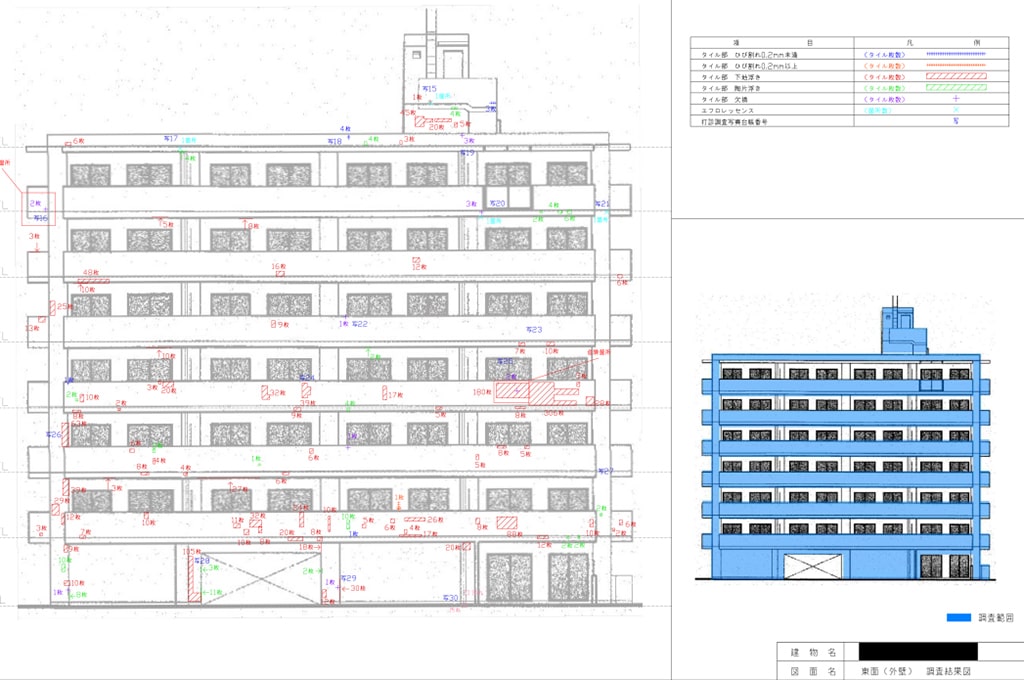

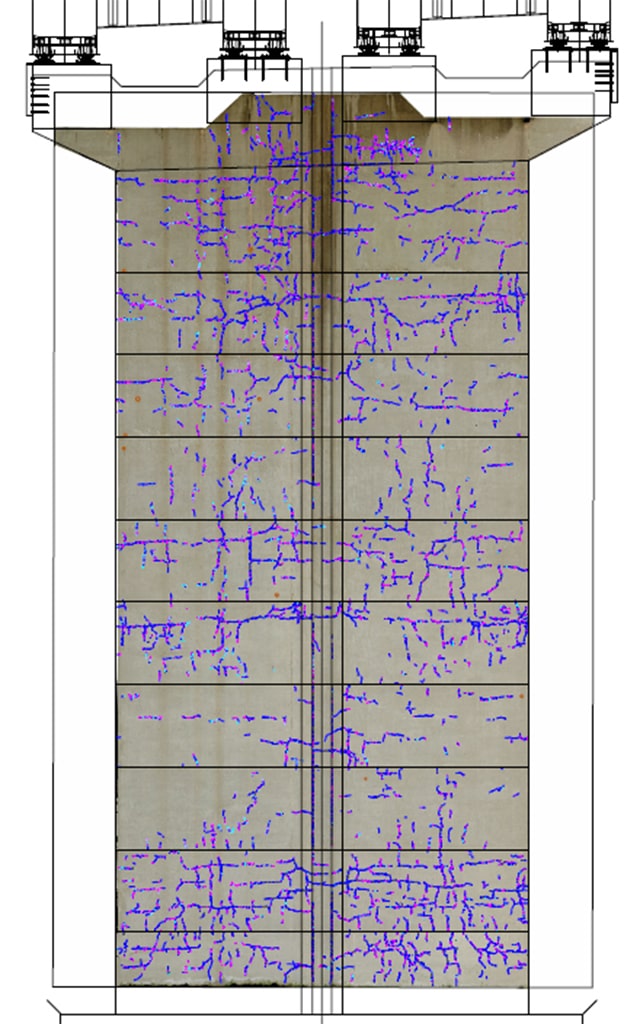

Capable of crack inspections over long distances and at high elevations

Ultra-high resolution and ultra-telephoto lens camera + automatic crack analysis system

The ultra-telephoto lens can capture cracks as small as 0.2mm from a distance of up to 200 meters. The captured visual images are corrected for tilt using the automatic crack analysis system 'Kuraves-Actis', which then automatically detects the cracks. Additionally, all images are stitched together into a single orthoimage, which can be overlaid with drawing data to clearly identify the location of the cracks.

Inspection Targets: Large bridge, high-rise buildings, etc.

Inspection Equipment: SONY α7 + 600mm ultra-telephoto lens, PhaseOne 150MP camera.

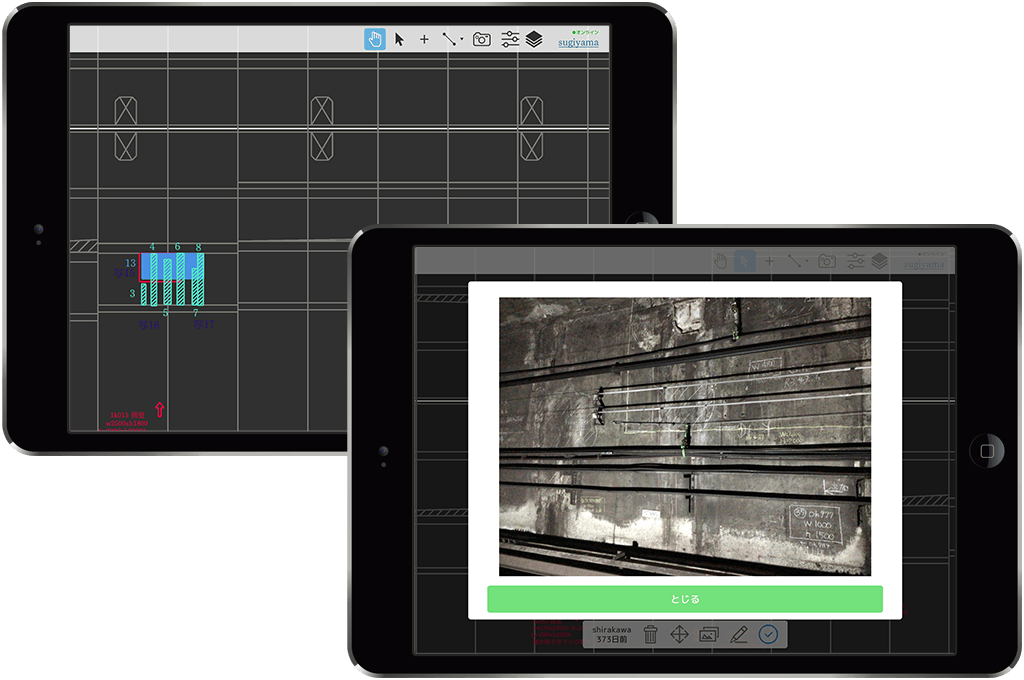

Integrated management from site inspection to reporting and review of repairs

Building and Structure Inspection App System

This is an app that enables integrated management of on-site inspections and report generation. By digitizing the previously handwritten inspection records into a tablet, you can create accurate reports including photo logs, quantity tables, and deterioration diagrams with a single click. Additionally, the inspection status can always be checked on the cloud, which helps in managing progress and improving the efficiency of site management.

Inspection Targets: All tiled buildings, concrete structures, etc.

Inspection Equipment: SmartST.