Crack Inspection of Structures

Efficiency in Crack Inspection through Digital Technology

The causes of cracks in concrete structures can vary, including drying shrinkage, temperature stress, corrosion of reinforcing bars, seismic events, and other disasters. Even in sound concrete structures, cracks occur to some extent. If cracks are left unattended, the reinforcing bars inside will eventually rust and expand. Moreover, when water penetrates, it reduces the strength of the concrete itself, necessitating early repairs.

Typically, crack inspections are conducted visually, but in recent years, digitalization has advanced, enabling accurate measurement of crack widths from captured visible images. At Sugitec, we utilize our proprietary AI solution "Smart Crack Checker" for automatic crack extraction, as well as Kurabo's "Kuraves," to provide efficient and objective inspection results.

The Strengths of Concrete Structure Inspections

We employ automatic analysis techniques using software for crack analysis and extraction, automatically extracting crack lengths and widths. For the visual images of the subject objects crucial for analysis, we utilize systems such as "High-resolution DSLR + Telephoto Lens," capable of capturing high-resolution images even from long distances, and "150-megapixel cameras" capable of recording wide areas in ultra-high resolution. These methods enable us to achieve imaging capabilities not possible with conventional cameras, establishing efficient and cost-effective approaches without the need for scaffolding.

A system enabling long-distance photography and high-altitude photography without the use of drones.

[Super telephoto high-resolution camera] SONYα7RⅣ+600mmLens

With a super telephoto lens, it's possible to record cracks in structures from a distance of about 200 meters with a resolution of 0.2mm, enabling safer inspections. Additionally, it allows for high-angle photography from the ground, eliminating the need for drones and reducing costs.

- Image resolution: 61 million pixels

- Maximum shooting distance: 200 meters

- Detectable crack width: 0.2mm

The ability to capture a wide area in ultra-high resolution allows for significant reduction in shooting time.

[1.5 billion pixel camera] PhaseONE IXM-RS150F

Conventional cameras require getting close to the subject and conducting multiple shots, which takes time and poses safety concerns. With a 150 million-pixel camera, it's possible to capture the structure over a wide area in a single shot, ensuring both safety and efficiency during the photography process.

- Image resolution: 150 million pixels

- Maximum shooting distance: 50 meters

- Detectable crack width: 0.2mm

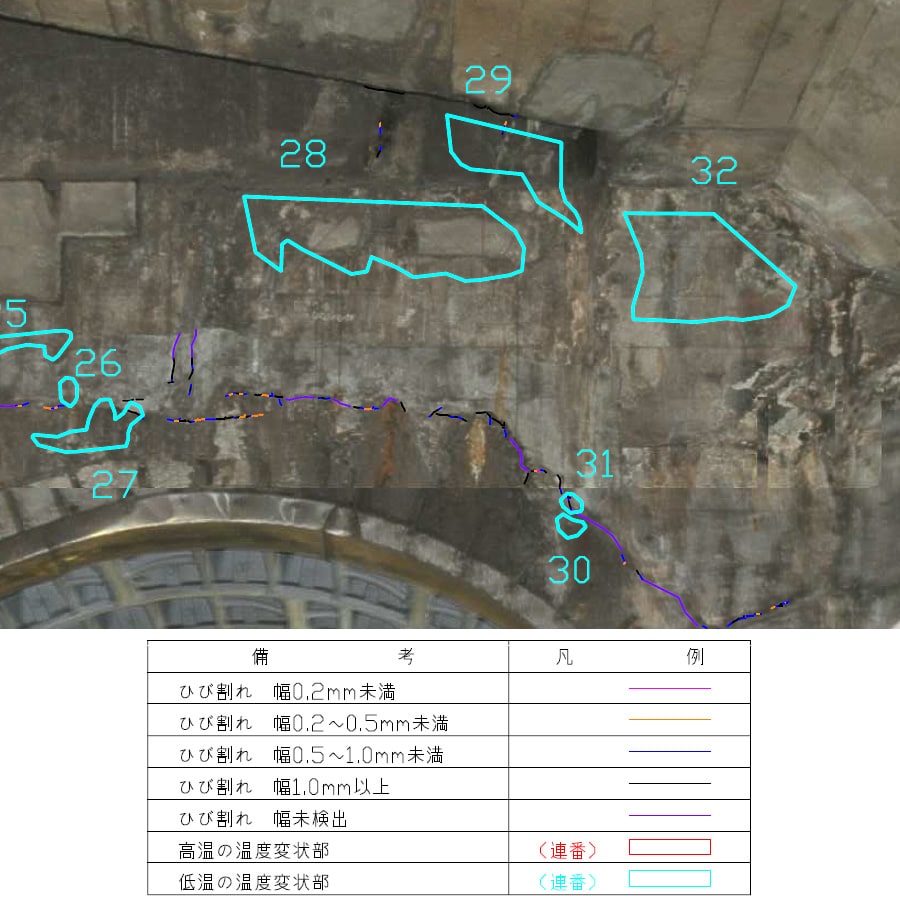

Analysis Case: Infrastructure Structure

- CRACK INSPECTION -

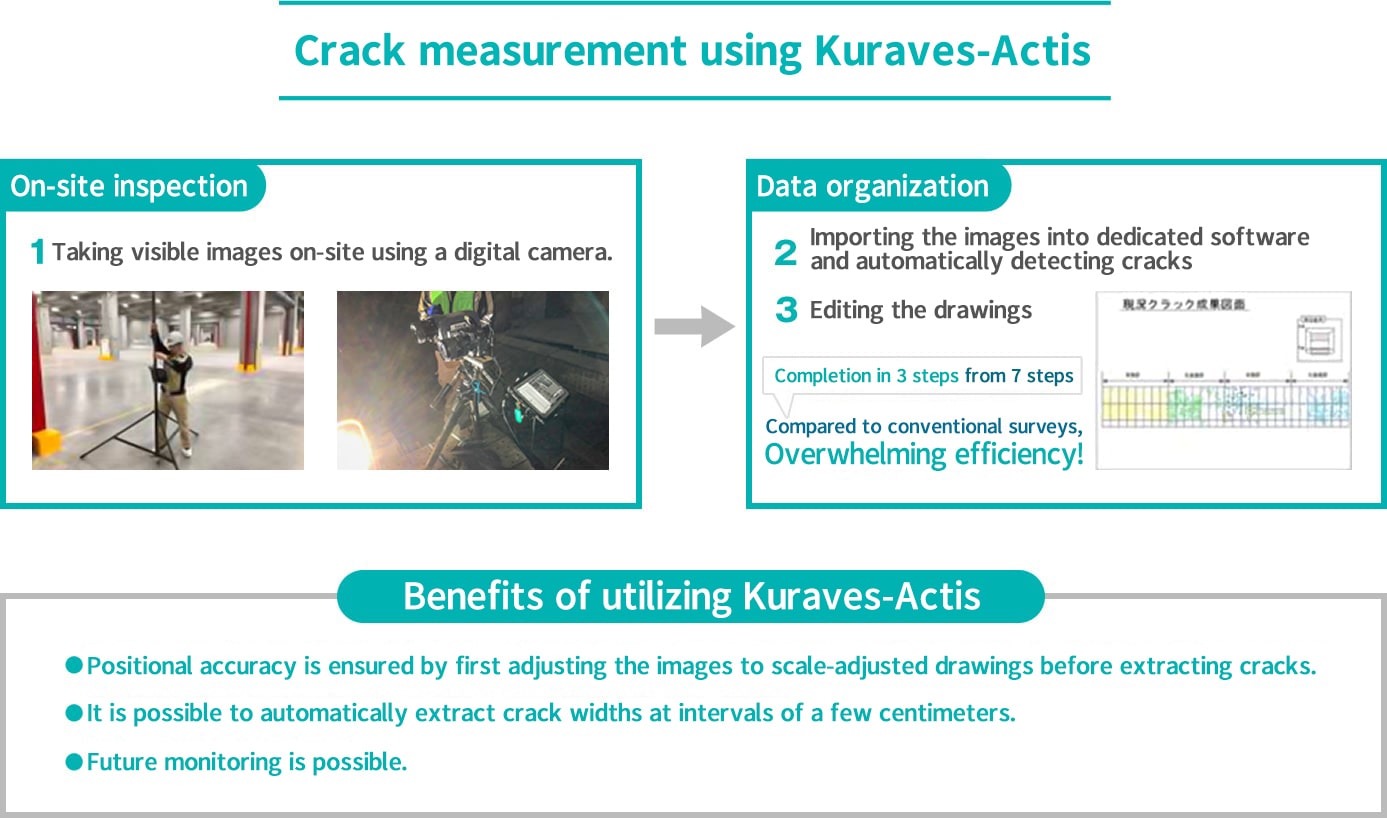

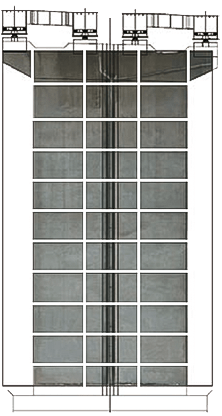

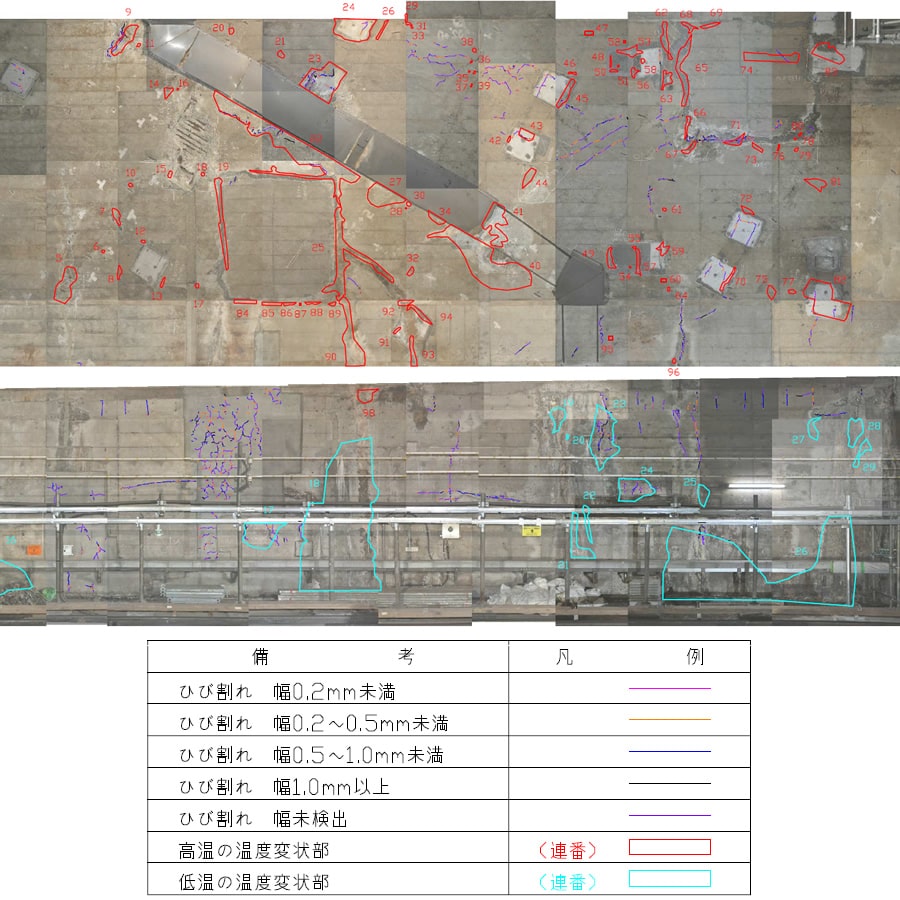

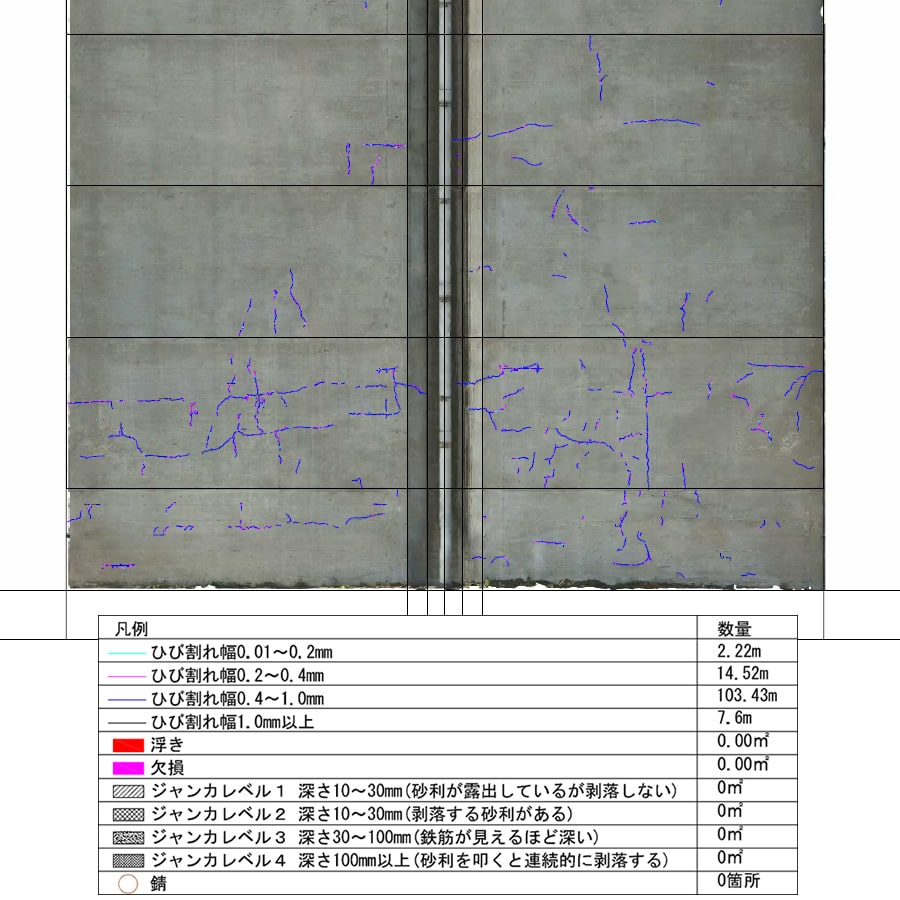

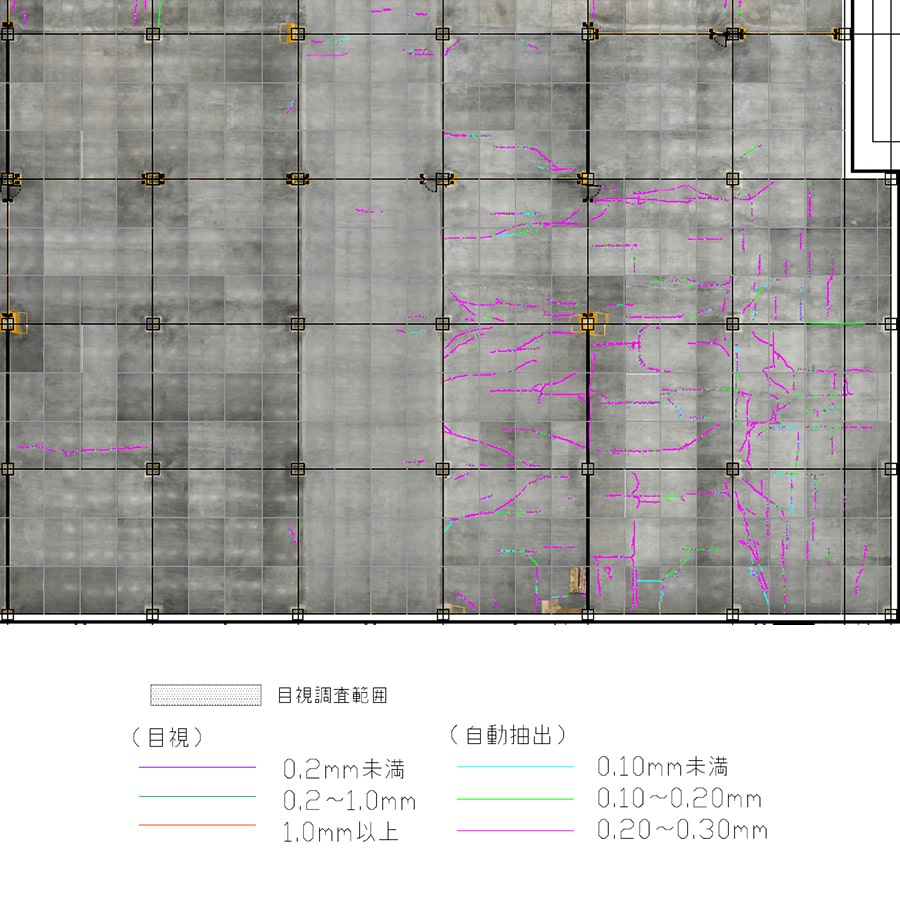

The captured visible images are processed through specialized analysis software. In the following case, the visible images of a bridge pier captured from the ground undergo "parthpective processing" to produce orthoimages. These orthoimages are then automatically analyzed using the software "Kuraves."

The software automatically detects and color-codes crack widths and lengths. Furthermore, by superimposing the extracted results onto the drawings and visible images, the precise locations of the cracks can be determined.

(Analysis results can be output in formats such as jpg, bmp, dxf, csv, etc.)

Case Study: Internal Wall Inspection of a Certain Subway Station-1

Case Study: Internal Wall Inspection of a Certain Subway Station-2

Case Study: Inspection of a Certain Bridge Pier

Case Study: Inspection of a Certain Logistics Warehouse Slab

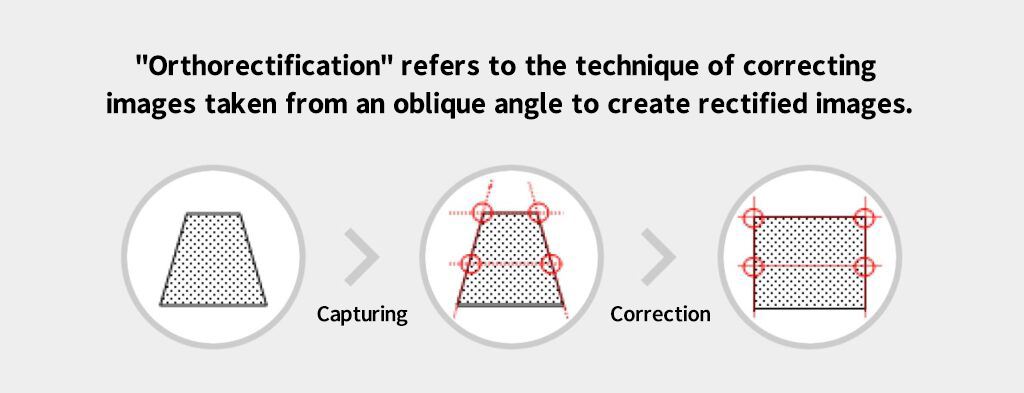

※The technique of "Perspective Correction (Tilt Correction)" refers to correcting images taken from an oblique angle, such as from bottom to top, to produce rectified images. By performing perspective correction, rectified images can be overlaid with images of structures, enabling the identification of precise locations of degradation in position information.

Furthermore, by overlaying both visible images and thermal images, it becomes possible to confirm information regarding dirt, cracks, etc., obtained from visible images against temperature variations in thermal images. This makes analysis easier and improves accuracy.

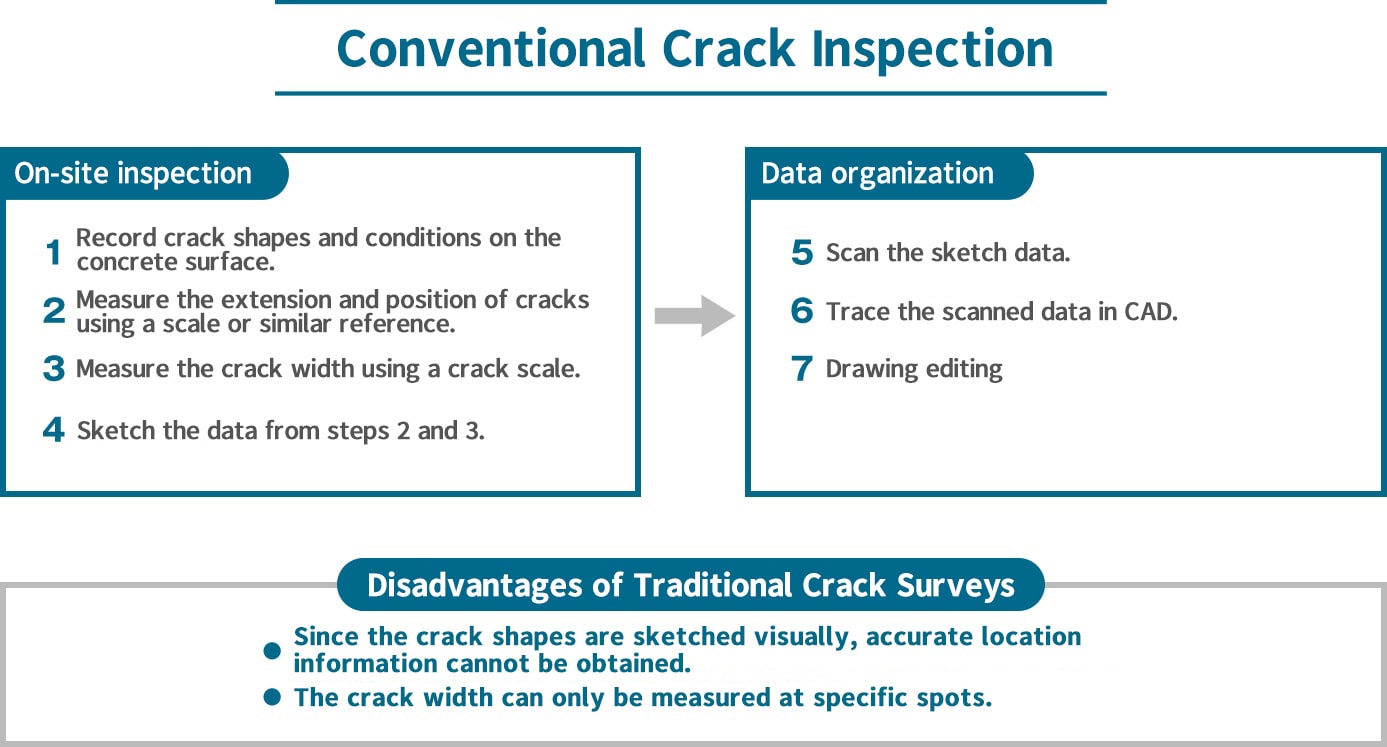

Comparison with Traditional Crack Inspection Workflow

- CRACK INSPECTION -

The diagram below compares the workflow of traditional crack inspection with Kuraves-Actis, a crack measurement system. It illustrates a significant improvement in efficiency in both on-site inspection and data processing compared to conventional analog inspections.