Floor Crack Inspection

Logistics facilities with growing needs Floor slab cracking Inspection

In order to maintain the aesthetics, durability, and seismic resistance of concrete structures over the long term, it is important to control the occurrence of cracks in the concrete. There are various factors that can cause such cracking, including shrinkage due to loss of moisture in the concrete and cracking from floor deflection caused by settlement due to the dead weight of the floor concrete.

Recently, logistics facilities are on the increase due to the flourishing online shopping market and the rapid progress of robotic logistics transport systems. Cracks in the concrete floor slabs of such facilities can have a significant impact on operations. We can meet your needs with quick and accurate surveys that combine our knowledge gained from years of extensive surveys of concrete structures with solutions that make work more efficient.

Crack investigation of concrete floor surface

Survey techniques for objective and accurate crack extraction

Cracks always occur in concrete. When cracks occur, not only do they cause aesthetic problems, but they also pose a growing problem of durability performance. Therefore, it is important to understand the width and progression of cracks from the initial stage.

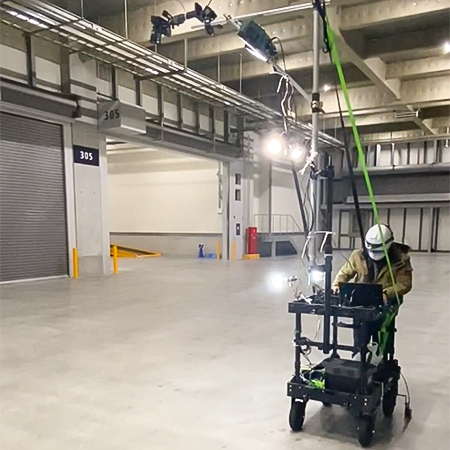

Conventional surveys using manual sketches are subject to the possibility of human error, such as omissions, and are also extremely time-consuming and costly in the case of vast distribution facilities. We use the “Large Plane Photography Technique” to efficiently photograph large floor surfaces, and our proprietary AI analysis software “Smart Crack Checker” for image analysis to realize efficient work.

Smart Crack Checker

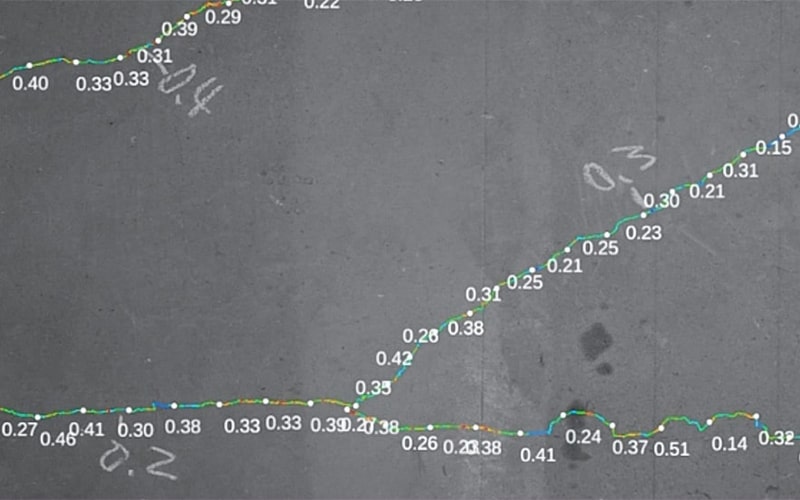

Smart Crack Checker automatically corrects the visual image taken and generates an ortho image. From the generated ortho image, cracks are automatically extracted by tracing cracks.

By utilizing AI in the system, accurate data on cracks and length can be measured on the visual image.

Smart Crack Checker Features

Unique Units「Large Plane Photography Technique」

This is a mobile imaging unit that can internally perform automatic correction + automatic composition by managing the imaging position in rows and acquiring images of the same correction value for each row. Compared to conventional survey methods, it is possible to photograph large floor surfaces in a shorter time.

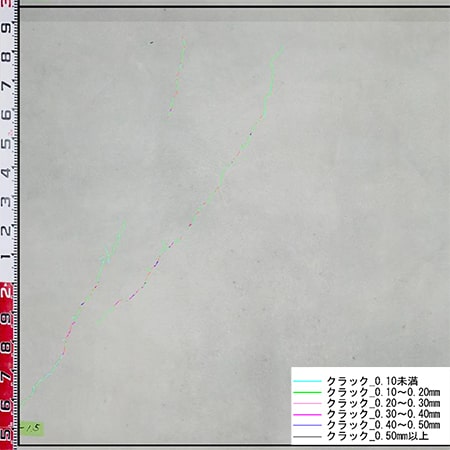

AI judgment + automatic crack mapping function

AI detects potential crack curves from the image and automatically predicts the width of the cracks. The predicted cracks are visualized and output in an easy-to-understand color-coded format by width.

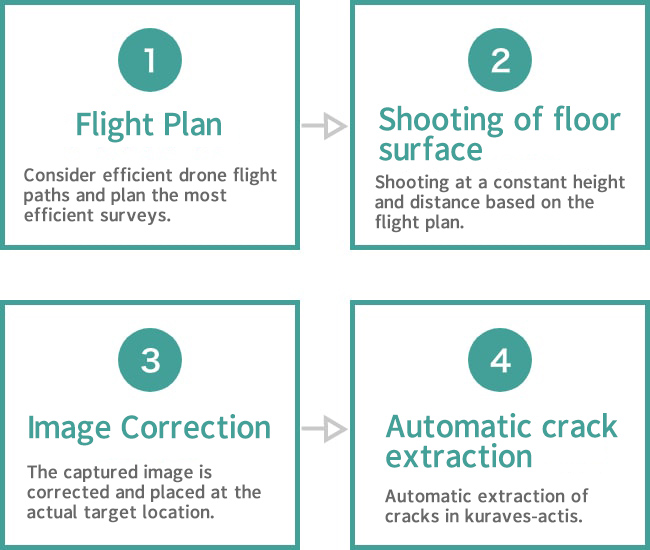

Flow of crack detection with Smart Crack Checker

Other methods: example of crack survey by drone

- FLOOR CRACK SURVEY -

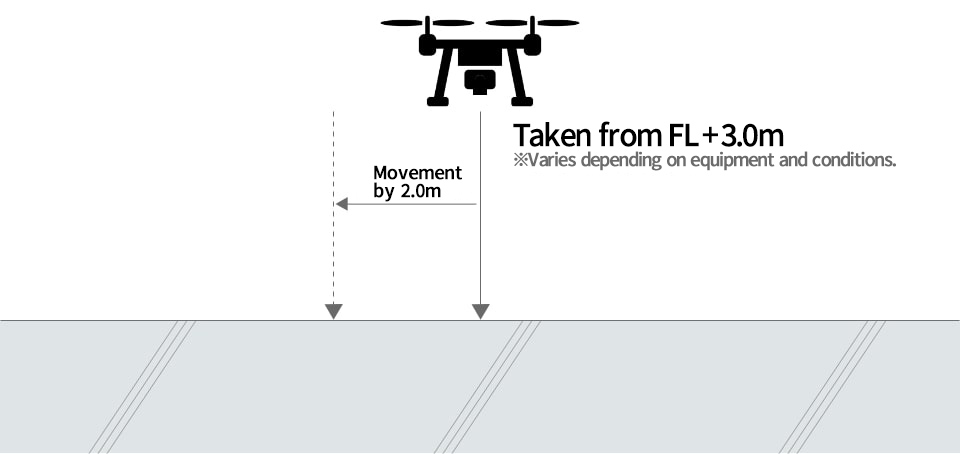

Recently, drones have been increasingly used to improve operational efficiency. We also use drones to survey the exterior walls of buildings, and are expanding their use to survey the concrete floors of logistics warehouses. In the case of large logistics facilities, it sometimes takes time to take photographs even with the digital single-lens reflex (SLR) system introduced above. In such cases, the use of a drone can drastically shorten the shooting time.

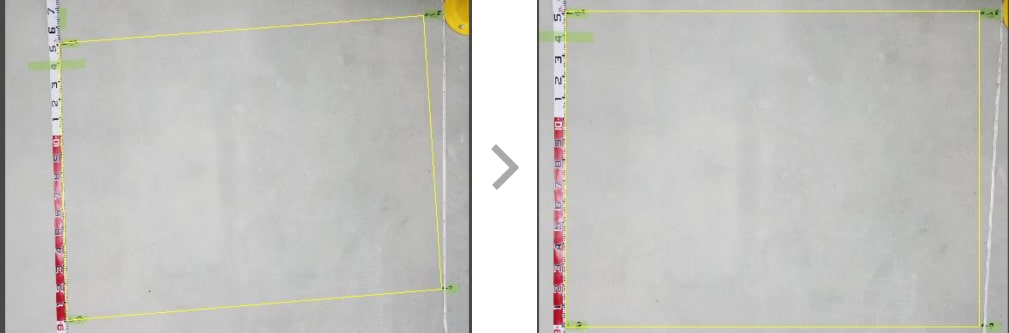

Image Correction (perspective Correction)

In order to accurately extract degradation, there are always problems that need to be corrected in images captured by a camera, such as image distortion caused by camera lens characteristics, such as “barrel aberration,” in which the image expands outward, and “filament aberration,” in which the image contracts inward, and angular tilt during shooting, as in the image above.

Our system compensates for all of these factors at once, improving the accuracy of automatic crack extraction and enabling the identification of deterioration information at the exact location.

Example of floor crack investigation

- FLOOR CRACK SURVEY -

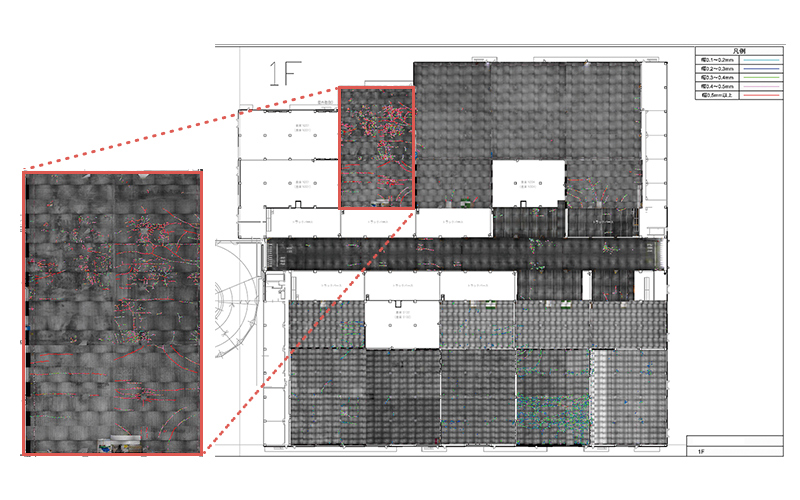

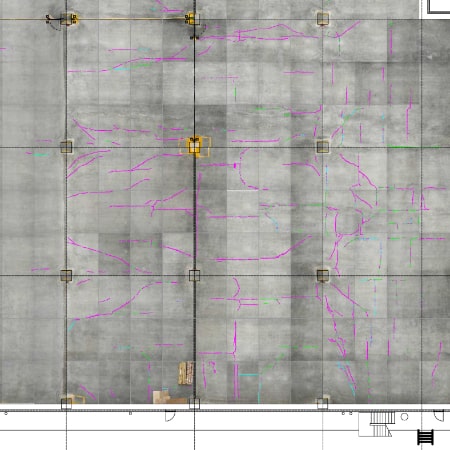

Recently, floor slab crack investigation is in high demand, mainly in logistics warehouses. This is an example of a survey of a logistics warehouse we have conducted. We provide services from the investigation to the submission of a report, and if repairs are required, we will take the necessary measures to address the problem.

01 A certain advanced logistics facility-1

The efficiency of a survey can be dramatically increased by using a drone to photograph the floor surface. And the more sophisticated the drone, the more efficient it becomes.

02 A certain advanced logistics facility-2

The images acquired by the drone are automatically corrected by the dedicated software, which also automatically analyzes the width of cracks so that cracks smaller than 0.2 mm are not missed.

03 A certain large-scale logistics facility-1

Even for large logistics facilities, the ability to automatically correct from the acquired captured images is an advantage not found in manual work. We provide quantitatively high-quality results regardless of experience.

04 A certain large-scale logistics facility-2

We have established a method that allows us to acquire high-quality data quickly and efficiently, no matter who is doing the photographing. The larger the survey target, the more obvious the difference from conventional survey methods becomes.