Fiberscope inspection

Versatile applications from machinery and equipment diagnostics to internal structural inspections.

Industrial endoscopes (fiberscopes) are one of the non-destructive inspection methods widely utilized for inspecting and diagnosing the interiors of infrastructure structures such as buildings, bridges, piping, and machinery and equipment where direct visual inspection is not feasible.

Equipped with an integrated camera and light, it captures real-time photos and videos of the interiors of structures, enabling visual confirmation of the inspection target's condition. This capability allows for the evaluation of structural degradation and other factors.

Investigating structural changes from the inside

Generally, the installation of exterior wall tiles onto concrete structures such as buildings involves applying a base mortar to the frame, followed by mortar for affixing the tiles. The exterior cladding material, such as tiles, is then adhered to this surface.

In such structures, deterioration of the mortar due to aging can lead to delamination and cracking, necessitating repair work such as resin injection methods. Prior investigation, including locating and determining the depth of delamination, is essential before conducting repair works. Additionally, post-repair quality assurance inspections can also be facilitated.

A system enabling reliable inspection and diagnostics with high-quality, sharp, and low-noise images.

[Industrial endoscope] OLYMPUS IPLEX-R IV9420RX

With a high-definition image sensor and Olympus' proprietary image processing processor, 'PulsarPic,' finely detailed, low-noise, and sharp images can be obtained. This allows for faithful reproduction of the subject with sharp and clear images, enabling high-reliability inspections and diagnostics.

- Image resolution: H768×V576

- Insertion tube outer diameter: Φ4.0mm

- Measurement functions: Two-point measurement, line reference measurement, surface reference measurement, etc.

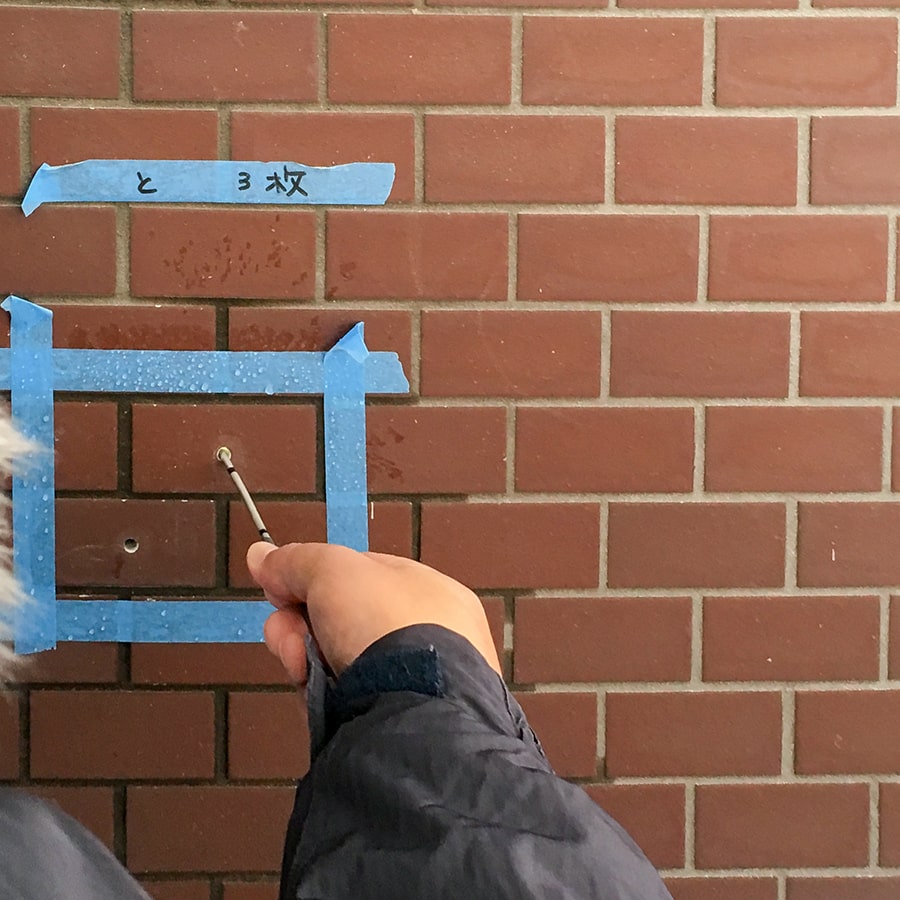

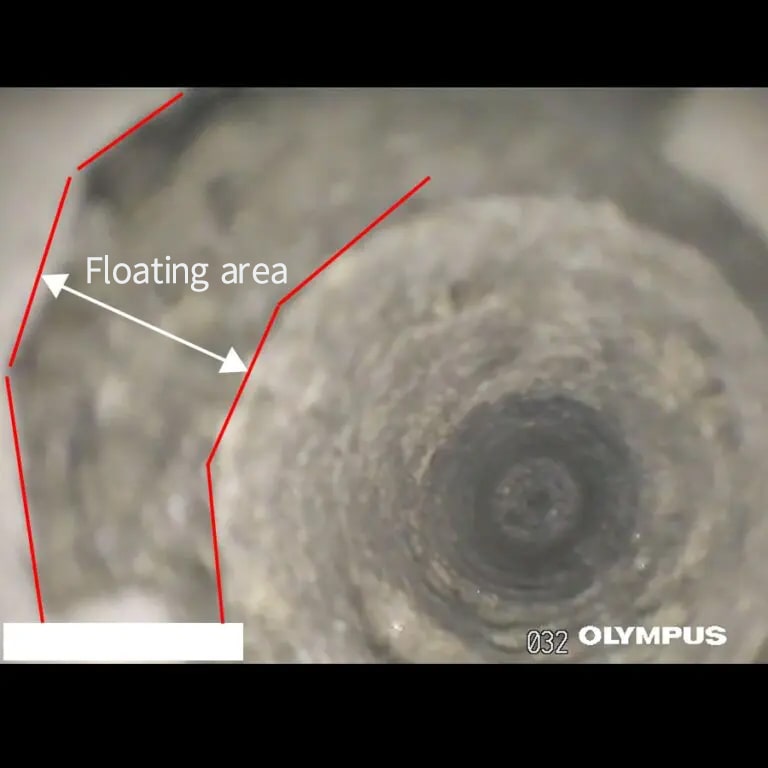

Case study: Inspection of Floating Subsidies and Floating Interfaces at a Certain Apartment Complex

- FIBERSCOPE INSPECTION CASE -

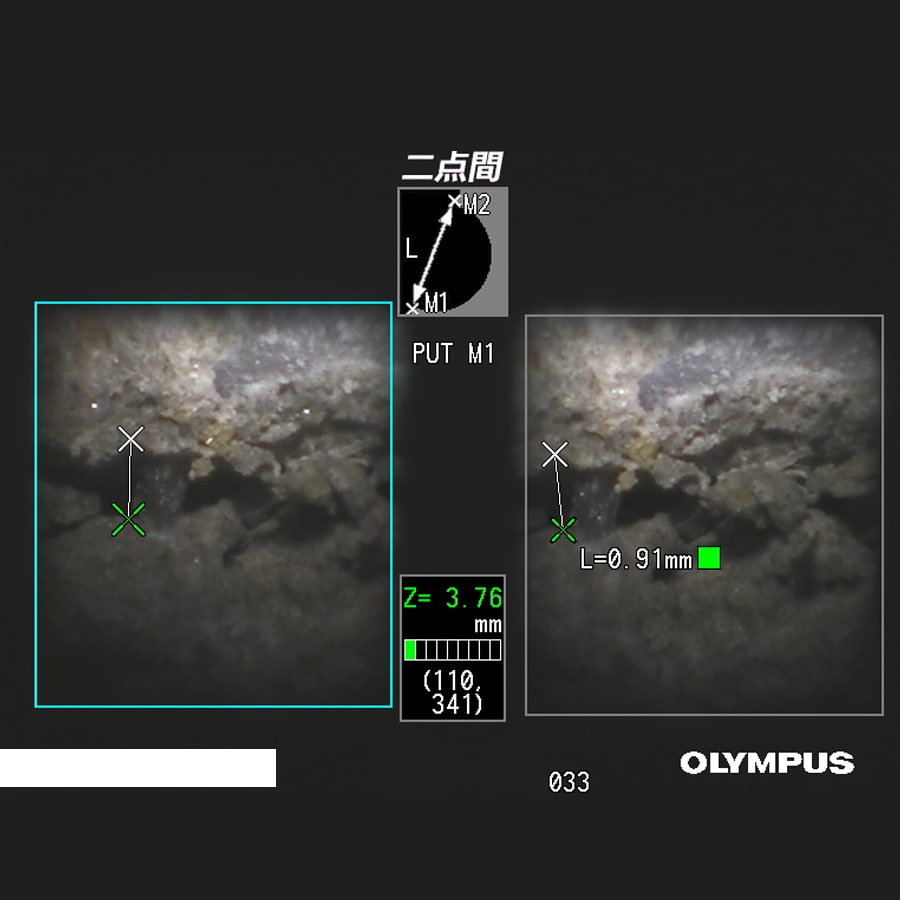

Using a fiberscope, we conducted an inspection of the protruding sections of exterior wall tiles to confirm the floating allowance and the floating interface (interface between the concrete structure and the affixed mortar). As a result, the floating allowance was determined to be 0.91mm.

Step1: Perforation of Tiles with a Non-impact Drill.

Step2: Inspection of Perforated Holes Using a Fiberscope.

Step3: Verification of Internal Conditions.

Step 4: Confirmation of Gap Width Using Two-Point Measurement.

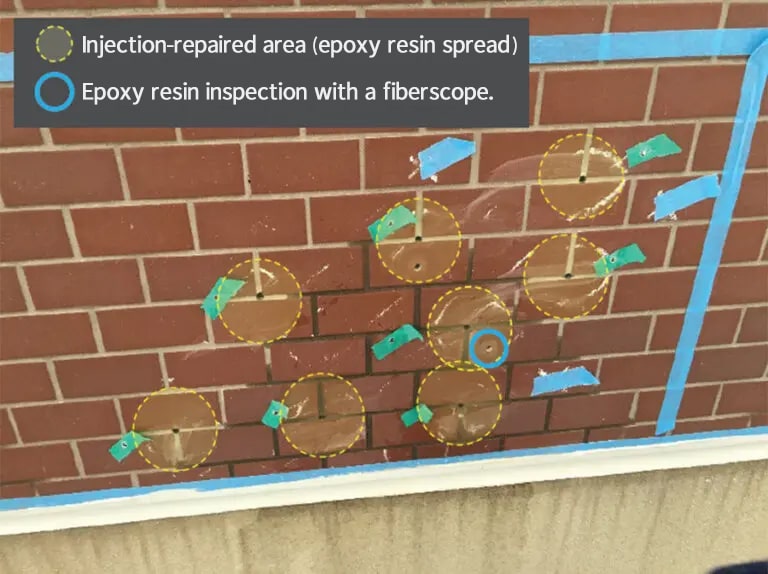

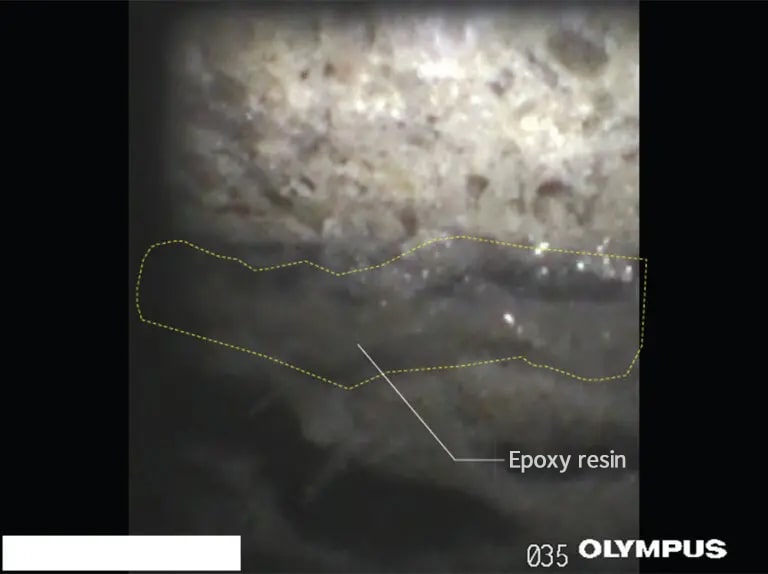

Quality Verification of Injection Repair Work in the Floating Section

Confirmation of the Resin Coverage Area in the Injected Repair Section.

Verification of the Injected Material Condition with the Fiberscope.

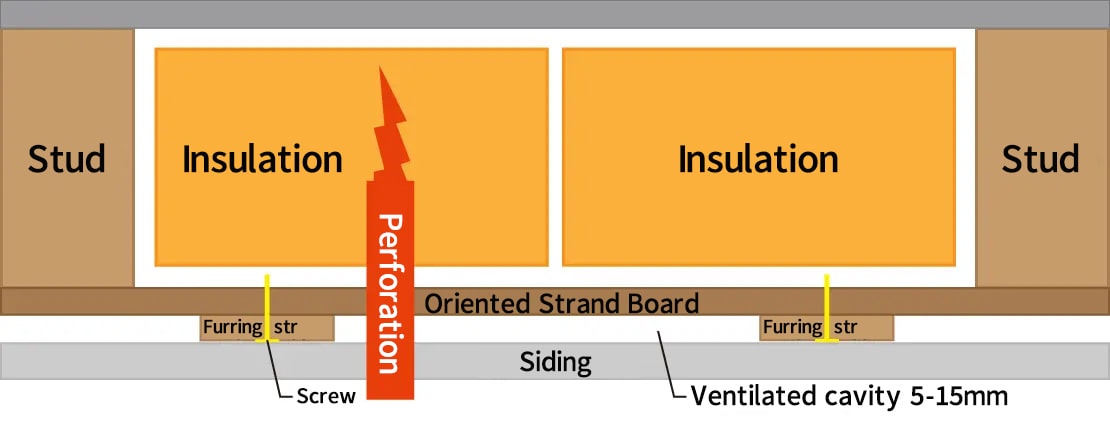

Utilization Case: Verification of Wall Internal Condition in a Certain 2x4 Construction Property

- FIBERSCOPE INSPECTION CASE -

The 2x4 construction method boasts numerous advantages such as seismic resistance, wind resistance, air tightness, insulation, and fire resistance. It has become widely adopted in Japan due to its cost-effectiveness and shorter construction period compared to traditional methods. However, its high level of air tightness and insulation can lead to condensation issues caused by temperature differentials between the interior and exterior of the building. Particularly, hidden areas such as within walls are prone to condensation, which may result in deterioration of the structure from within.。

Generally, inspecting the condition within walls is challenging with this construction method. However, by utilizing a fiberscope, it becomes possible to thoroughly examine the internal condition of walls.