Infrared survey

The key lies in acquiring appropriate capture data and leveraging reliable insights to derive accurate results.

These days, there are many highly efficient inspection tools available that significantly streamline building surveys. By utilizing such equipment, inspections can be conducted relatively easily by anyone, and result data can be obtained.

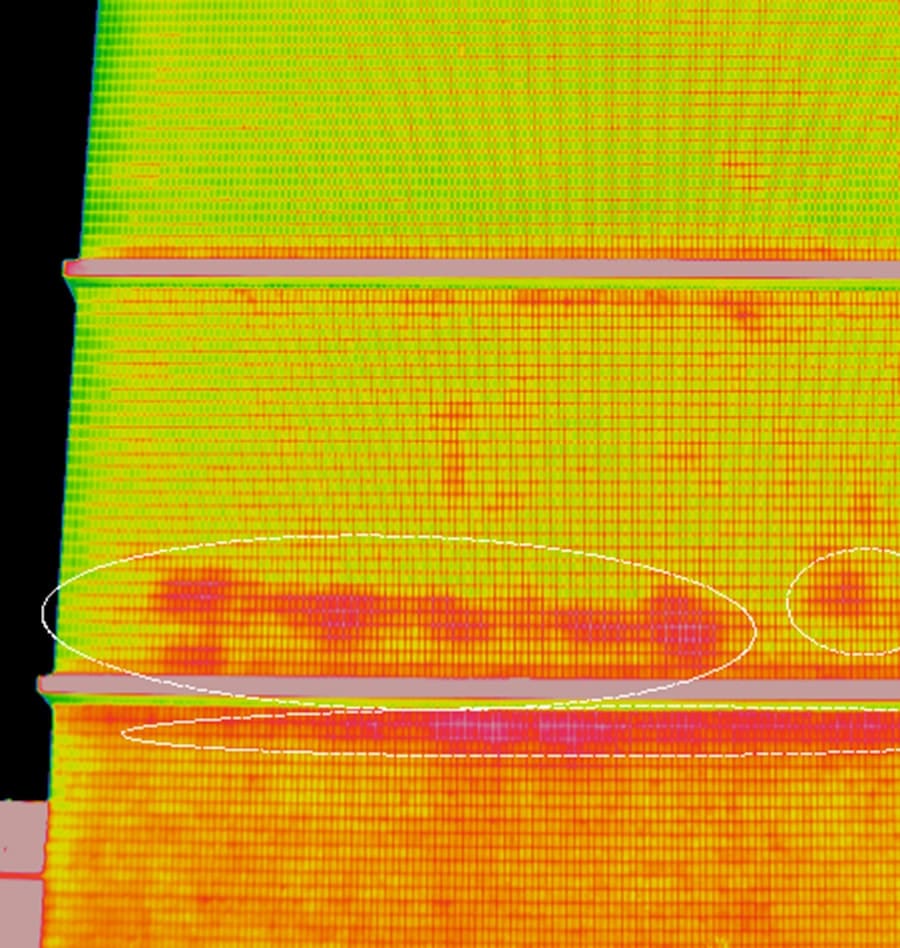

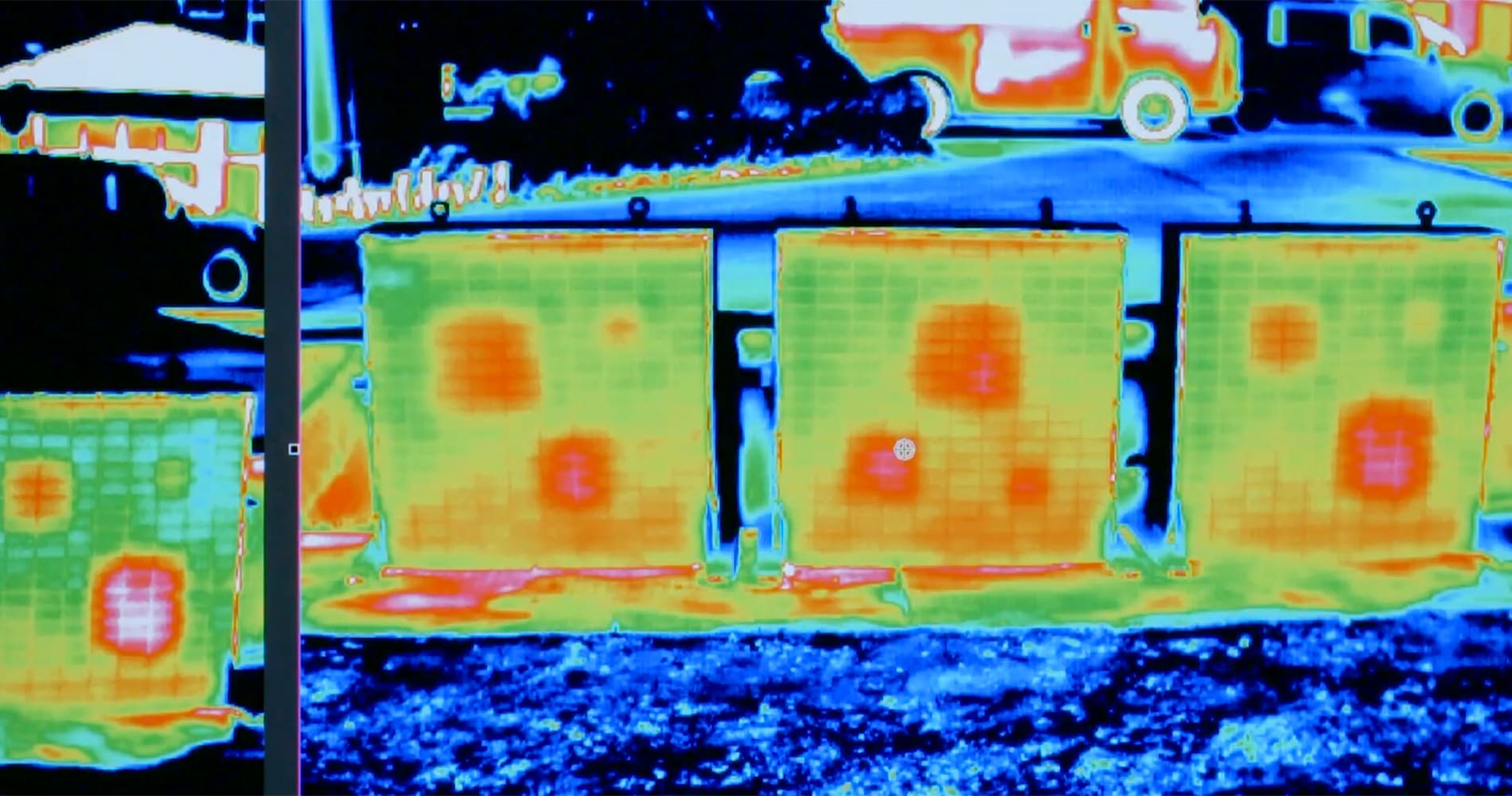

However, the experience and knowledge to discern appropriate deteriorated areas from the data analysis of inspection results are crucial. Especially with thermal images from infrared cameras, deterioration cannot be easily determined solely by changes in color.

Exterior wall inspection using an infrared camera

Infrared exterior wall inspection ensures safe and reliable assessments. This non-destructive testing method also helps to keep costs lower compared to traditional inspections.

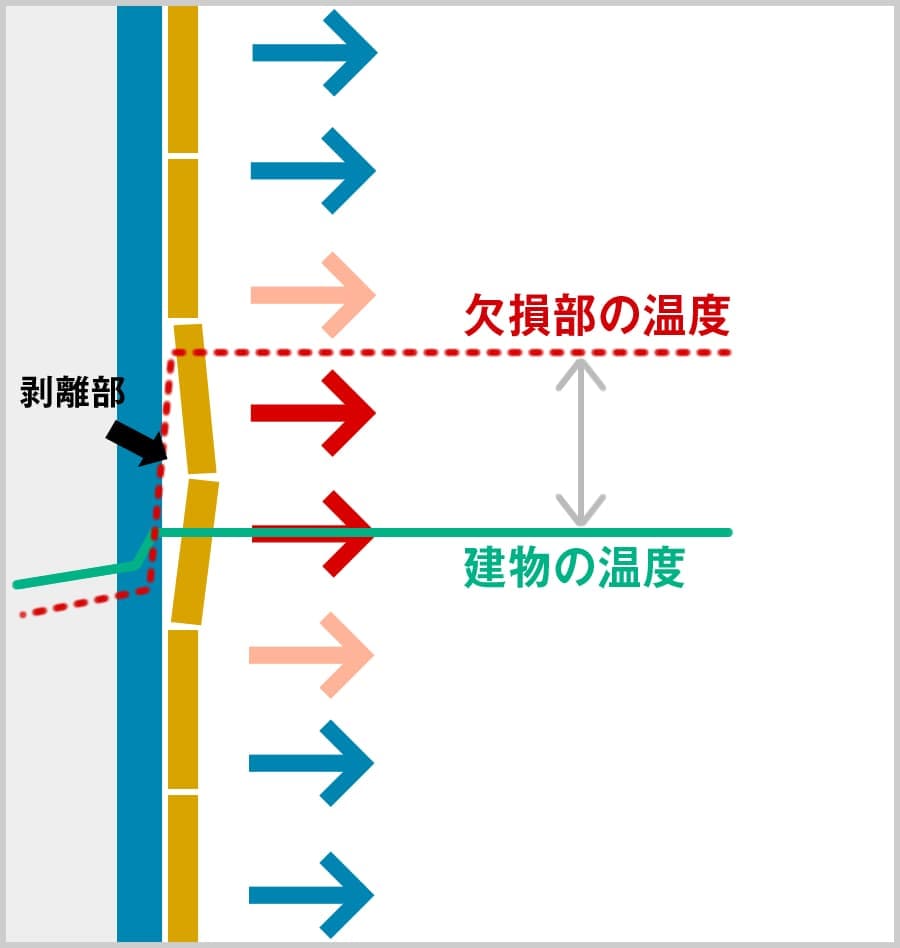

The infrared inspection method visualizes the surface temperature of the subject through a thermographic camera. It is a non-destructive testing technique used to diagnose internal defects or deterioration based on temperature variations. For instance, if there is a detachment in exterior wall tiles, it creates thermal resistance in the air layer behind, causing a temperature difference with the healthy parts. This abnormal temperature distribution helps identify deteriorated areas.

Causes of temperature increase in peeling areas of exterior wall tiles

The thermal energy from solar radiation is transferred and absorbed from the exterior wall tiles to the structural concrete of the framework. During this process, deteriorated areas where detachment creates an air gap between the tile and mortar tend to retain heat more effectively on the backside, leading to elevated temperatures compared to intact sections.

When captured by an infrared camera, these elevated temperature areas (air gaps = detachment) manifest as a red hue, indicating high temperatures.

Surveys conducted prior to the revision of the periodic reporting system.

- INFRARED THERMOGRAPHY SURVEY -

In Ministerial Ordinance No. 282 issued by the Ministry of Land, Infrastructure, Transport and Tourism, the method for diagnosing exterior walls after 10 years of completion or exterior wall renovation work was specified as "comprehensive percussion testing using a test hammer." For buildings, especially those that have exceeded 10 years since construction or renovation, particularly hazardous exterior wall surfaces must undergo a comprehensive inspection.

After the revision of the periodic reporting system, infrared camera diagnosis became possible as well.

- INFRARED THERMOGRAPHY SURVEY -

Originally, the method for diagnosing external walls was limited to "percussion testing with a test hammer," but under the supervision of the Housing Bureau of the Ministry of Land, Infrastructure, Transport and Tourism, "diagnosis using an infrared camera" has also been recognized. In recent years, infrared camera diagnosis has attracted attention as an alternative method to full-surface percussion testing.

Advantages and Disadvantages Compared to Percussion Testing

- INFRARED THERMOGRAPHY SURVEY -

Cost-wise, infrared inspection proves to be highly advantageous compared to percussion testing, but it's not without its drawbacks. Here, we'll outline the pros and cons of infrared inspection compared to percussion testing.

The advantages of infrared inspection include

- Scaffold costs are unnecessary and relatively inexpensive.

- No noise is generated during the inspection.

- In the case of mortar with a paint finish on the exterior, it is possible to detect finer instances of detachment depending on the situation, compared to percussion testing.

- The inspection time can be shortened.

- It's possible to visualize the delamination. Accurate damage location information can be obtained through image correction.

The disadvantages of infrared inspection include

- There are challenges in stabilizing the analysis accuracy due to variations in finishing methods for each building and differences in the timing of image capture.

- Judgments may vary depending on the analyzer.

- Prone to be influenced by weather conditions.

- In the case of tiled finishes, it is difficult to identify the floating interface, making it challenging to directly link to construction proposals.

- There may be areas that cannot be photographed due to surrounding environmental and site conditions.

Infrared camera surveys also have drawbacks compared to tapping inspections. Especially, the inability to capture images due to surrounding environmental and site conditions essentially renders infrared surveys impossible. However, by combining other inspection methods, it is possible to conduct reliable surveys while keeping costs down.

Thermographic cameras used for infrared inspections

- INFRARED THERMOGRAPHY SURVEY -

Our infrared inspections utilize thermal imaging cameras from FLIR Systems, a leading global company in the infrared market. These highly reliable infrared inspection devices, widely used across various industries worldwide, feature both cooled and uncooled sensors, placing them at the top tier among infrared cameras. Additionally, for inspections in locations inaccessible from the ground, such as tall buildings, we complementarily employ infrared drones.

Ideal for the construction sector, it boasts the highest class of uncooled sensor pixel and temperature resolution, ensuring compatibility with a wide range of buildings.

[Uncooled infrared cameras] FLIR T1040

As a non-cooled infrared camera, it features a high-resolution detector and proprietary optical system, enabling clear imaging and accurate temperature measurement. It allows for precise diagnostics in various scenarios and across all types of buildings, ensuring no potential issues go unnoticed.

- HD resolution. It also enables thermal image generation of up to 3.1 million pixels.

- The temperature resolution is best in class at 0.02°C.

Ideal for civil engineering applications. A cooled infrared camera capable of capturing temperature variations even in environments without direct sunlight.

[Cooled infrared camera] FLIR A6701sc

A cooled infrared camera equipped with the state-of-the-art detection sensor, Antimonide Indium (InSb). With precision to capture temperature changes of less than 0.02°C, it enables non-destructive testing of concrete structures in places like underground areas and tunnels where sunlight doesn't reach.

- It demonstrates its effectiveness in diagnosing civil engineering structures such as subways and tunnels.

- Ideal for surveys on the north side of buildings without direct sunlight.

For high-rise buildings and other structures that are difficult to capture with infrared imaging from the ground, we use drones equipped with infrared cameras.

[Infrared drone] DJI Matrice300 RTK

Equipped with high-precision navigation and positioning systems, this DJI flagship industrial drone is inspired by aviation systems in its design. It features advanced AI capabilities, six-directional sensing and positioning technology, and a multitude of other functions, enabling it to conduct surveys in a wide range of scenarios.

- It enables infrared inspections of areas beyond the reach of ground-based photography, such as high-rise buildings.

- It can be used in environments where a standard camera cannot provide sufficient shooting distance.

Experience in inspecting civil structures using cooled infrared cameras.

- INFRARED THERMOGRAPHY SURVEY -

Infrared inspections are effective for civil structures as well. Particularly, high-precision cooled infrared cameras can capture temperature changes even in structures located in environments without sunlight exposure, such as underground areas.

Cases of conducting inspections in sites like tunnels where there is no direct sunlight.

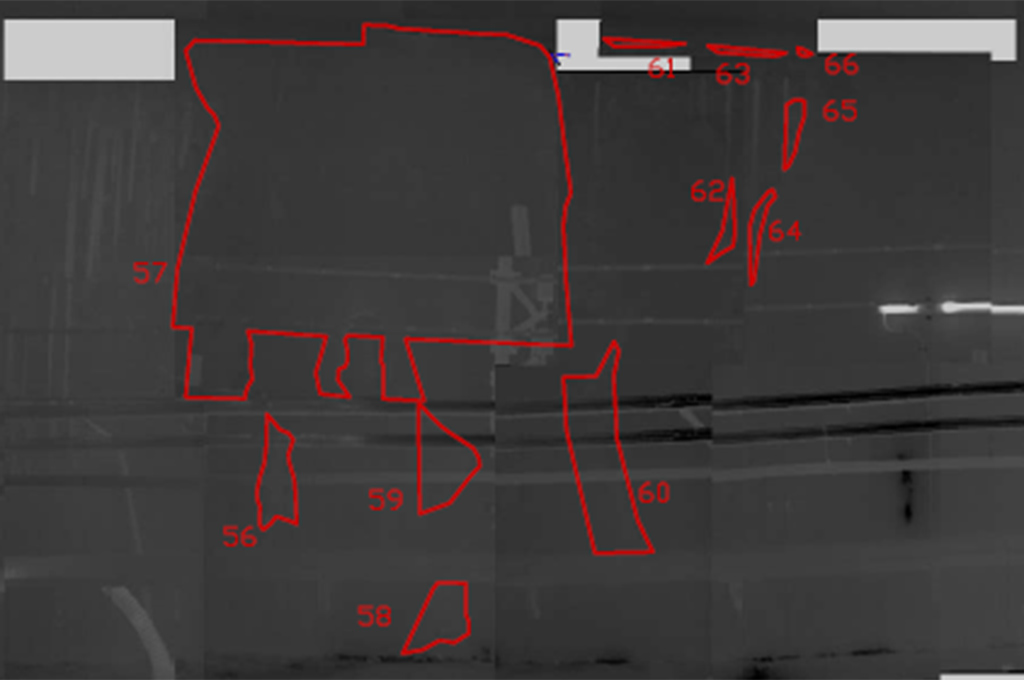

Subway Inner wall inspection

Civil structure infrared inspection record

Inspection of deterioration in the sidewall sections of subway lines.

In subway tunnels and similar environments unaffected by sunlight, there's a method of artificially heating the concrete surface using heat sources, but it requires time and costs. By utilizing cooled infrared cameras, diagnostics can be conducted in their natural state, thus reducing both time and expenses.

Environments with little temperature variation, such as the north face, can also be surveyed.

Inspection of elevated bridges

Civil structure infrared inspection record

Investigation of floating, cracks, etc. on the outer surface of piers.

Since it doesn't receive direct sunlight, inspecting for delamination on north-facing surfaces is typically challenging unless conditions are ideal. However, with a cooled infrared camera, detection is possible even in environments where the external temperature is not very high.

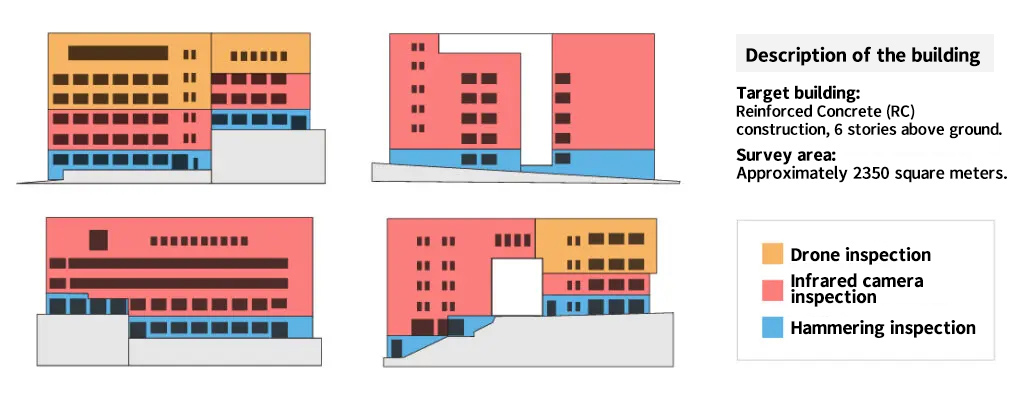

We propose the optimal combination of inspection methods tailored to the situation.

- INFRARED THERMOGRAPHY SURVEY -

Depending on the site conditions, for example, if capturing images with an infrared camera is challenging, we can photograph only the accessible areas and combine this with hammering inspections using gondolas or rope access for the difficult-to-reach areas. This approach can be more cost-effective than setting up scaffolding for a full-scale hammering inspection. We provide flexible solutions to help reduce costs based on the situation.

【Case studies】Inspection using a combination of hammering, ground photography, and drone photography